By Anne Manning

CSU Source

Across Colorado State University’s campus, most research operations have gone quiet in the wake of COVID-19 pandemic restrictions. But there’s one lab at the Energy Institute’s Powerhouse Energy Campus still working around the clock.

The Rapid Prototyping Lab at Powerhouse has special clearance for a fast-mobilization project launched in direct response to the daily-changing pandemic. Over the last two weeks, CSU engineers and infectious disease researchers have been developing a low-cost sprayable disinfectant that kills SARS-CoV-2 – the virus that causes COVID-19 – and that can be brought to market quickly, thanks to a partnership with Fort Collins design firm Czero.

The core technology for the new disinfectant is based on the same principle CSU disease researchers are currently testing for a vaccine against the novel coronavirus – work also being done at an accelerated pace at the Infectious Disease Research Center. The technology deactivates the virus by rendering it incapable of replicating through a combination of specific wavelengths of light and targeted nucleic acid chemistry.

Those disease research efforts are led by Raymond Goodrich, professor in the Department of Microbiology, Immunology and Pathology and executive director of the Infectious Disease Research Center, where testing on the new disinfectant is now taking place.

“What we are attempting to do is see if we can scale up Ray’s technology to do large-scale disinfection of surfaces,” said Bryan Willson, executive director of the CSU Energy Institute and professor in the Department of Mechanical Engineering. “So think of classrooms, stadiums, auditoriums.”

Existing technology, new application

About two weeks ago, Willson and Goodrich discussed the idea of using Goodrich’s technology, which uses riboflavin, a B vitamin, and ultraviolet light to deactivate pathogens, in a different application: a commercial disinfectant spray. A cleaning product wouldn’t require the rigorous animal and human testing needed for vaccines and drugs, and such a product could be developed and vetted within days at the Rapid Prototyping Lab.

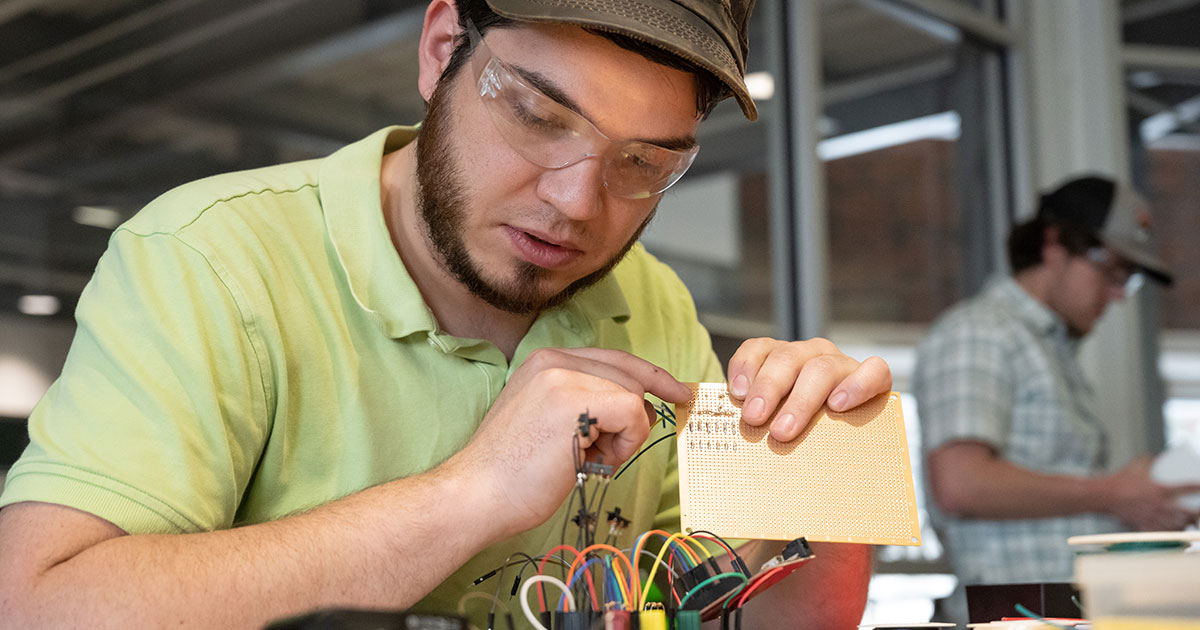

The lab, led by Energy Institute research engineer John Mizia, specializes in designing and fabricating products for scientists across campus to use in their experiments. In fact, Goodrich, Mizia and Willson had been working together for about a year on making various devices for Goodrich’s ongoing work with bloodborne pathogens – long before the COVID-19 pandemic.

“I think one of the core benefits we can bring is timing,” Mizia said. “Obviously with the pandemic happening now, the ability to rapidly bring together a team and designs and put that into an actual product is amazing. Shortening the timeline in a critical situation like that is paramount. And having a facility like this to rapidly jump on something is incredibly important.”

The Rapid Prototyping Lab, launched a year ago, supports research and innovation across campus all the time, not just during a crisis, Mizia said.

Partnering with design firm

For the disinfectant project, Willson pulled in the help of Czero, a Fort Collins engineering design firm that, as a startup company, once occupied space in the Powerhouse. Its vice president of engineering, Chris Turner, received his engineering education at CSU in the 1990s. Czero offered its product design expertise without hesitation, and the entire team held their first design meeting on Sunday, March 15.

“Czero is excited to be part of this project,” said Guy Babbitt, company CEO. “We have a long history of working with CSU and Powerhouse on difficult projects like this. What I like about working with researchers at CSU is that they are able to move very quickly, but still do rigorous engineering. That is a great fit for us and is exactly what is needed in this situation.”

Since that first meeting, the team at Powerhouse has fabricated blood well plates, light delivery mechanisms and timing circuitry that will allow the disinfectant to be tested against the actual coronavirus in the university’s Biosafety Level III facility on the Foothills Campus. Testing with the virus should start this week.

The disinfectant is aimed at being fast, safe and environmentally friendly, Goodrich said. “We will be testing the ability of the devices to kill this agent on common surfaces,” he said. “This is critical because current studies have shown that the virus can persist on surfaces for up to 72 hours.”

If virus testing is successful, the disinfectant will move into product and commercialization stages with Czero at the helm. The end product would be a backpack-like sprayer combining the riboflavin solution with a specially designed LED light system. Details around initial designs remain proprietary, but the team hopes to have a product available to the public, best suited for industrial settings like schools and stadiums, in coming weeks.

It takes a team

Willson said the team’s mobilization is a prime example of how CSU and its surrounding partners can deliver solutions to problems quickly – more quickly than a traditional, walled-off academic setting.

“People often think of innovation as the lone inventor, but in fact it’s the broader network put together to get things done rapidly,” Willson said.

According to Goodrich, “the strongest teams to me are the ones that reflect us as a society and reflect us as an institution. It’s the difference that bringing together these diverse talents and knowledge pools represents in taking on daunting challenges, that truly determine a path to success or to failure. I cannot see how we could achieve what we have been able to achieve without efforts and collaborations like this.”

Support Northern Colorado Journalism

Show your support for North Forty News by helping us produce more content. It's a kind and simple gesture that will help us continue to bring more content to you.

BONUS - Donors get a link in their receipt to sign up for our once-per-week instant text messaging alert. Get your e-copy of North Forty News the moment it is released!

Click to Donate