Self-driving Teslas are neat but lack the functionality any forward-looking farmer would want in a cutting-edge autonomous vehicle: sharp cutting edges and high-powered lasers capable of incinerating 50 weeds per second.

In the not-so-distant future, a once unthinkable option is on the table as Colorado fruit and vegetable growers continue their struggle to recruit, retain and afford enough farm workers to weed and harvest their produce. The latest crop of agricultural robots is beginning to fill the gaps left by farm labor shortages.

“The technology might seem totally sci-fi,” says Adrian Card, CSU Extension’s statewide specialty crop expert, “but that future is already here. It’s becoming a reality.”

Although replicating the dexterity of human hands to harvest crops continues to be a daunting task, destroying weeds has proven to be lower-hanging fruit.

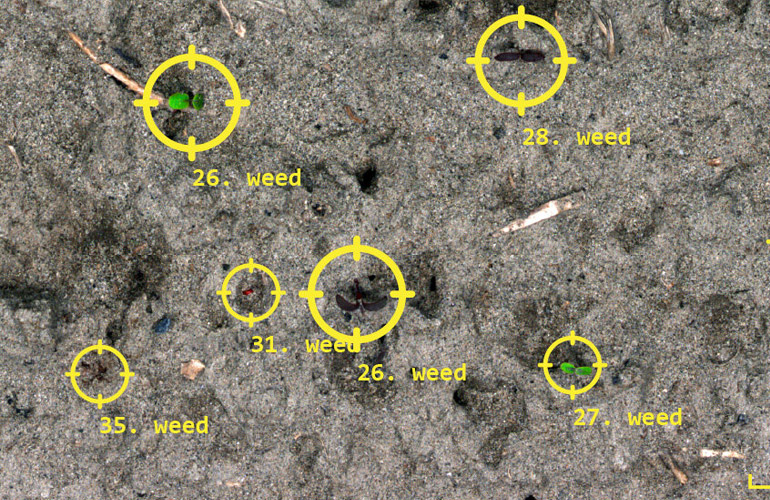

With AI vision, machine learning, high-powered carbon dioxide lasers, and dizzying arrays of oscillating blades, these robots have been designed to inflict maximum devastation on unsuspecting weeds.

The largest models boast the capability to clear two acres of weeds in an hour, leaving neat rows of untouched produce in their wake.

Who the technology is for

Card has been immersed in autonomous farming technology for the past few years, working to understand better how these innovations could help Colorado producers and bringing ag-tech leaders to the state to share their insights.

“Our goal is to get growers in Colorado aware of, and connected with, this technology so that they can make the best decision for their farm for sustainability and for profitability,” said Card in an interview with KSIR.

For Colorado fruit and vegetable producers, labor costs can account for up to 50% of their total operating expenses, according to preliminary data collected by Card and Ali Hill, Ph.D., an assistant professor with CSU’s Department of Agricultural and Resource Economics.

“Farms that have large payroll costs are going to find this the most attractive,” continued Card. “The robotics companies are trying to find a price point that has a return on investment for many farms within about three years.”

The cost of Ag Robots

The price of the different technologies varies, but the most advanced options – such as the laser weeder – will likely be hard to justify for small and mid-sized operations, according to Card.

Carbon Robotics, headquartered in Seattle, Washington, Stout Ag Tech, based in Salinas, California, and Barn Owl Precision Agriculture, based in La Junta, Colorado, recently demonstrated their robotic weeders in Rocky Ford, Colorado organized by CSU Extension. Representatives from Verdant Robotics and Naio Technologies were also at the demonstration to answer questions.

“This doesn’t have to be all million-dollar machines. It is possible to come up with some cost-effective solutions,” said Steve Fennimore, a UC Davis weed scientist, during a presentation on autonomous weeders organized by Card.

“There’s a whole new set of technologies that’s just emerging, and I think it has room to run for a long time,” added Fennimore.

The impact on farm labor markets

For over a hundred years, the number of people required to work in the fields to make a farm functional has been precipitously dropping as technology has advanced from horse-drawn plows to the countless innovations that producers have access to today.

In 1870, the year CSU was founded, more than 50% of workers in the United States were in the agriculture industry. Today, that number is 10%, with only 1 in 10 of those workers employed directly on farms.

Extension’s Card sees agricultural robots and the economic pressures on farm operators, contributing to that trend.

“[Farm operators] love the people that they work with, and the thought of needing to replace their workers because of cost – to replace humans with machines – it kind of bums them out, to be frank,” said Card in his interview with KSIR.

But with the slow adoption of robots on farms, he doesn’t see a doomsday scenario for farm workers anytime soon.

“Even as the technology continues to progress and becomes more affordable and widely accessible, you need people in the decision-making loop. You need them to perform maintenance and support the operations,” Card said.

“In most instances, we’re going to see people working alongside advanced technologies, but that workforce will likely continue to shrink,” he continued.

Card compared working as a farm laborer to working in grocery stores, where the starting salaries are roughly the same, but supermarkets gain an edge by offering air-conditioning.

“Weeding crops is a demanding job that isn’t in high demand among workers,” said Card. “From a broader perspective, these automated technologies will help farms stay viable and continue contributing to their local economies by providing jobs, even if there are less of them.”

Support Northern Colorado Journalism

Show your support for North Forty News by helping us produce more content. It's a kind and simple gesture that will help us continue to bring more content to you.

BONUS - Donors get a link in their receipt to sign up for our once-per-week instant text messaging alert. Get your e-copy of North Forty News the moment it is released!

Click to Donate