Setting up a pharmaceutical laboratory requires meticulous planning and an understanding of the various equipment and procedures that will form the backbone of your operations. Among the crucial tools in the lab arsenal, a titrator stands out as a key player. It’s essential for accuracy in various testing procedures, and choosing the right one can significantly impact the efficiency and precision of your lab work.

Understanding Titration in a Pharmaceutical Context

Titration, a fundamental process in any pharmaceutical laboratory, involves measuring the concentration of a substance in a solution. It’s a critical step in ensuring the quality and composition of pharmaceutical products. In the fast-paced and exacting world of pharmaceuticals, having a reliable titration system is not just important; it’s a central aspect of maintaining high standards. When it comes to sourcing a titrator, one can consider Metrohm, a reputable provider known for precision in their titration systems. Their products ensure that your lab’s measurements are accurate and reliable, a non-negotiable in pharmaceuticals.

Essential Features of Titrators for Pharmaceutical Labs

When delving deeper into the world of titrators, it’s important to focus on the features that make them suitable for pharmaceutical applications. The complexity and sensitivity of pharmaceutical compounds call for equipment that can deliver precision and consistency. Key features to look out for include automated functionality, data logging capabilities, and compliance with regulatory standards.

Automated titrators, for example, bring efficiency and reduce human error, vital in a field where precision is paramount. Data logging is another feature that cannot be overlooked. In an industry governed by stringent regulatory requirements, having a detailed record of every titration is crucial for quality control and audit purposes. Moreover, equipment compliance with standards such as ISO and GLP ensures that your lab operations are up to global norms.

Navigating Regulatory Compliance and Quality Assurance

Setting up a pharmaceutical lab is not just about having the right equipment; it’s also about understanding and adhering to the regulatory landscape. The pharmaceutical industry is heavily regulated to ensure the safety and efficacy of products. Compliance with regulations such as Good Laboratory Practice (GLP) and Good Manufacturing Practice (GMP) is non-negotiable. These regulations dictate not just the quality of the pharmaceutical products but also the processes and equipment used in their development.

Quality assurance is a continuous process in a pharmaceutical lab. It involves not only the consistent application of standards but also regular verification and calibration of equipment like titrators. Ensuring that your equipment is regularly serviced and calibrated by accredited professionals is key to maintaining the integrity of your lab’s output.

Incorporating Advanced Technology in Lab Setup

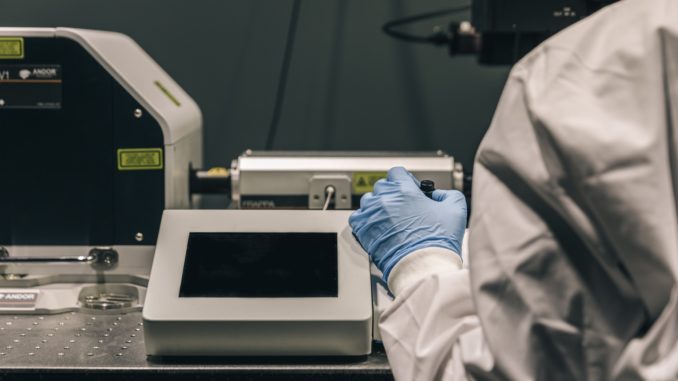

As the pharmaceutical industry evolves, the technology used in laboratories must keep pace. Advanced titrators are now equipped with features like touch-screen interfaces, integrated software solutions, and connectivity options. These advancements not only streamline the titration process but also integrate it seamlessly with other lab systems. This integration is vital for a holistic approach to data management and analysis, ensuring that all information is easily accessible and interpretable.

The integration of technology in titrators also opens the door to more complex analyses. Modern titrators can handle multiple titrations simultaneously, offer diverse titration methods, and provide more precise control over the titration process. This flexibility and precision are crucial in a field where the compounds and reactions involved are often complex and varied.

The Role of Training and Expertise

Investing in sophisticated titrators is only one part of the equation. The skill and expertise of the personnel operating these machines are equally important. Comprehensive training ensures that lab staff are not only adept at using the equipment but also understand the underlying principles of titration and its applications in pharmaceutical analysis.

Regular training sessions, workshops, and seminars can keep lab personnel updated on the latest trends and techniques in titration. Collaborating with equipment suppliers like Metrohm for specialised training can be particularly beneficial. These sessions can provide in-depth knowledge about specific equipment, ensuring that your team can make the most of the technology at their disposal.

Mitigating Risks and Ensuring Safety in the Lab

Safety is paramount in a pharmaceutical lab, where the handling of chemicals and reactions can pose significant risks. Proper use and maintenance of titrators play a crucial role in mitigating these risks. Ensuring that titrators are well-maintained, calibrated, and operated according to safety guidelines helps prevent accidents and ensures the safety of lab personnel.

It’s essential to establish safety protocols around the use of titrators. This includes proper training on handling chemicals, understanding emergency procedures, and using personal protective equipment (PPE). Additionally, regular safety audits and inspections can help identify and rectify potential hazards in the lab environment.

Sustainability and Efficiency in Lab Operations

In today’s context, sustainability is an increasingly important aspect of laboratory operations. Titrators that are energy-efficient and designed with eco-friendly considerations in mind can contribute significantly to reducing the environmental footprint of your lab. Additionally, choosing titrators with long service lives and minimal need for consumables can enhance the overall efficiency and cost-effectiveness of your lab operations.

Efficient operation of titrators also involves optimising their usage to reduce waste and maximise output. This can be achieved through proper planning of titration schedules, regular maintenance to ensure optimal performance, and using automation to reduce the need for repetitive manual tasks.

Embracing Future Trends and Innovations

The pharmaceutical industry is one that is constantly evolving, with new discoveries and technologies emerging regularly. Staying abreast of these changes and adapting your lab accordingly is crucial. Future trends in titration may include more advanced automation, integration with artificial intelligence for predictive analysis, and further miniaturisation to save space and resources.

Preparing your lab for these future trends involves not only keeping an eye on emerging technologies but also fostering a culture of innovation and continuous improvement. Encouraging staff to stay informed about industry advancements and exploring opportunities for research and development can position your lab at the forefront of pharmaceutical innovation.

In conclusion, setting up a pharmaceutical lab is a complex but rewarding endeavor. Understanding and incorporating the right titrators is a vital part of this process. From ensuring accuracy and efficiency in your experiments to complying with regulatory standards and embracing future trends, titrators are central to the success of a pharmaceutical lab.

Support Northern Colorado Journalism

Show your support for North Forty News by helping us produce more content. It's a kind and simple gesture that will help us continue to bring more content to you.

BONUS - Donors get a link in their receipt to sign up for our once-per-week instant text messaging alert. Get your e-copy of North Forty News the moment it is released!

Click to Donate